Hosiery fabric is one of the most widely used knitted textiles in the apparel industry, prized for its softness, stretchability, and comfort.

From everyday essentials like undergarments and T-shirts to specialized garments such as sportswear and socks, hosiery fabric plays a vital role in shaping modern fashion.

Its breathable texture and versatile nature make it a preferred choice for both manufacturers and consumers worldwide.

In this complete guide, we’ll explore everything about hosiery fabric, from its history, manufacturing process, and key types to its applications, benefits, and care tips, to help you better understand this essential fabric category.

What is Hosiery Fabric?

Hosiery fabric refers to a class of knitted fabrics known for their elasticity, lightness, and softness. Unlike woven fabrics, hosiery is produced by interlooping yarns, which gives it stretch and flexibility.

It’s commonly used in undergarments, loungewear, socks, tights, babywear, and activewear due to its comfort-focused properties.

Historical Background of Hosiery

The origins of hosiery can be traced back to the 16th century when knitted stockings became popular in Europe. With the invention of knitting machines, hosiery production became faster and more refined.

Over time, it evolved from wool and cotton knits to include synthetic fibers like nylon, polyester, and elastane, making fabrics more durable and versatile.

Great section outline! Let me elaborate your “Characteristics of Hosiery Fabric” into a more descriptive, blog-friendly version. Each characteristic will be expanded with examples and context, making it more engaging and informative.

Characteristics of Hosiery Fabric

Hosiery fabric stands out in the textile industry because of its functional and comfort-driven properties. These unique characteristics make it suitable for a wide spectrum of garments, ranging from delicate lingerie to sturdy casual wear.

Here are the key traits that define hosiery fabric:

Stretchability

One of the most defining features of hosiery fabric is its remarkable stretch. Unlike woven fabrics, which are rigid, hosiery fabrics are knitted, allowing the yarn loops to expand and contract easily.

This stretchability ensures a body-hugging fit that adapts to different shapes and movements without restricting comfort.

For this reason, hosiery fabrics are the backbone of tights, leggings, and innerwear, where flexibility and freedom of movement are essential.

Softness and Comfort

Hosiery fabrics are usually knitted with fine-quality yarns like cotton, nylon, or blended fibers that deliver a smooth, skin-friendly texture.

The softness of the material makes it perfect for garments that remain in constant contact with the body. This is why hosiery fabrics are the preferred choice for undergarments, slips, and babywear, where gentle touch and comfort matter the most.

Lightweight Yet Durable

Despite being thin and light in weight, hosiery fabrics offer impressive durability when crafted with strong fibers like nylon or polyester.

Their fine structure makes them easy to wear and breathable, while their inherent strength ensures resistance against frequent washing and stretching. For instance, hosiery socks and stockings are lightweight yet long-lasting, providing both functionality and style.

Breathability

The looped knit structure of hosiery fabric creates natural ventilation channels that allow air circulation. This makes it highly breathable and ideal for warm or humid climates, as it helps regulate body temperature and wick away moisture.

Cotton hosiery fabrics, in particular, are prized for keeping garments cool and fresh throughout the day.

Versatility

Perhaps the most impressive trait of hosiery fabric is its versatility. It can be manufactured in a wide range of weights, textures, and finishes to suit different purposes.

From sheer hosiery for lingerie and fashion wear to thicker interlock or rib knits for pajamas, T-shirts, and baby suits, the adaptability of hosiery fabrics ensures they remain relevant across multiple categories of apparel.

This is an excellent outline for a “Types of Hosiery Fabric” section. Let me expand it into a polished, detailed version suitable for a professional blog or guide, with clear explanations and practical examples for each type.

Types of Hosiery Fabric

Hosiery fabrics are available in a variety of forms, each designed to meet specific garment needs. Depending on the fiber content, knit structure, and finish, they offer different levels of softness, elasticity, durability, and style.

Here are the most common types of hosiery fabrics:

Cotton Hosiery Fabric

Made from natural cotton fibers, this fabric is soft, breathable, and gentle on the skin. Its ability to absorb moisture makes it a favorite for undergarments, T-shirts, vests, and loungewear.

Cotton hosiery is especially popular in tropical and humid climates, where comfort and breathability are top priorities.

Polyester Hosiery Fabric

Polyester hosiery fabric is lightweight, durable, and quick-drying, making it ideal for sportswear and activewear.

Unlike pure cotton, it resists shrinking and wrinkling, and when blended with elastane, it provides excellent flexibility for high-performance garments such as leggings, gym tops, and track pants.

Nylon Hosiery Fabric

Known for its strength, elasticity, and sheen, nylon hosiery is widely used in tights, stockings, and socks. It provides a smooth, glossy finish that enhances the look of fashion garments. Nylon hosiery is also highly durable, maintaining its shape and appearance even after frequent washes.

Spandex/Elastane Blends

Spandex (also called elastane or Lycra) is rarely used alone but is often blended with cotton, polyester, or nylon. Its role is to add extra stretch and recovery, ensuring garments fit snugly without sagging.

These blends are common in activewear, lingerie, and body-fit garments where flexibility and shape retention are essential.

Interlock Hosiery Fabric

Interlock is a double-knit structure that provides more thickness, durability, and insulation compared to single-jersey knits.

It has a smooth surface on both sides and excellent stability, making it suitable for pajamas, babywear, T-shirts, and gloves. Interlock fabrics are soft yet strong, combining comfort with strength.

Rib Hosiery Fabric

This type is characterized by its vertical ribbed texture, achieved by alternating knit and purl stitches. Rib fabrics are stretchier and more flexible than plain knits, which makes them ideal for collars, cuffs, waistbands, and undergarments. The ribbed design also adds a subtle stylish effect to garments.

Melange Hosiery Fabric

Melange fabric is created by blending fibers dyed in different colors to produce a heathered, multi-toned appearance.

This gives garments a fashionable, textured look while maintaining the softness and comfort of hosiery. It is commonly used in casual wear, T-shirts, and sportswear, where style and comfort go hand in hand.

Manufacturing Process of Hosiery Fabric

The production of hosiery fabric involves a combination of technical precision and material expertise. Each stage, from yarn selection to final inspection, ensures the fabric meets the requirements of comfort, elasticity, and durability.

Yarn Selection

The process begins with choosing the right type of yarn, as it directly influences the texture, strength, and stretch of the final fabric. Commonly used fibers include cotton, polyester, nylon, and their blends.

To enhance elasticity, spandex (elastane or Lycra) is often added. For example, a cotton-spandex blend provides both softness and stretch, making it ideal for undergarments, while nylon-spandex blends are preferred for stockings and sportswear.

Knitting Process

Once yarn is selected, it is knitted using circular knitting machines or flat knitting machines. These machines interloop yarns to form the fabric, giving it its characteristic stretch.

The machine gauge, the number of needles per inch, determines the fabric’s fineness. A high-gauge machine produces finer hosiery for lingerie and stockings, while lower gauges create thicker knits suitable for T-shirts and pajamas.

Dyeing and Finishing

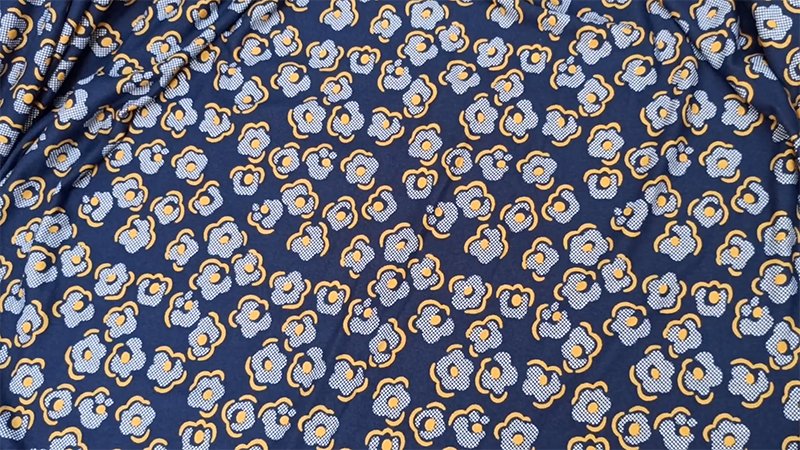

After knitting, the fabric undergoes dyeing to achieve the desired colors and patterns. Hosiery fabrics can be dyed solid, printed with designs, or given melange effects for a stylish heathered look. The dyeing stage is followed by finishing treatments, which may include:

- Softening for a smoother hand feel

- Compacting to reduce shrinkage

- Antimicrobial finishing to enhance hygiene for activewear and babywear

Quality Control

Before reaching garment manufacturers, hosiery fabrics are thoroughly tested for quality.

Key checks include:

- GSM (grams per square meter): Ensures consistent fabric weight

- Stretchability: Confirms elasticity and recovery

- Colorfastness: Checks resistance to fading after washing

- Durability: Evaluates wear and tear resistance

Applications of Hosiery Fabric

Thanks to its versatility, hosiery fabric finds applications across every segment of the apparel industry. Its adaptability to different weights, blends, and finishes makes it a universal favorite among designers and manufacturers.

Undergarments and Lingerie

Soft cotton and cotton-spandex blends are widely used for slips, panties, bras, camisoles, and other innerwear. The stretch and skin-friendly feel of hosiery fabrics make them perfect for body-hugging yet comfortable lingerie.

Casual Wear

Everyday garments such as T-shirts, tops, dresses, and pajamas frequently use lightweight hosiery fabrics. They provide style without compromising on breathability, making them a staple for loungewear and casual outfits.

Sportswear and Activewear

Moisture-wicking hosiery fabrics made from polyester or nylon blended with elastane are extensively used in activewear. These fabrics offer flexibility, quick-dry properties, and durability, making them ideal for leggings, yoga wear, gym tops, and athletic shorts.

Socks and Stockings

This category is dominated by nylon hosiery fabrics because of their elasticity, sheen, and strength. From sheer stockings and tights to thick winter socks, hosiery fabrics deliver comfort, stretch, and a polished finish.

Babywear

For infants, fabric softness is crucial. Interlock and rib hosiery fabrics are favored for baby suits, onesies, and pajamas because they are gentle on delicate skin and provide easy stretch for movement.

Industrial and Specialty Use

Beyond fashion, hosiery fabrics are also used in functional applications like gloves, uniforms, and medical wear. Their softness, flexibility, and breathable properties make them suitable for products requiring comfort with durability.

Advantages of Hosiery Fabric

Hosiery fabric has earned its place as a staple in the textile and fashion world thanks to its unique balance of comfort, functionality, and style.

Its adaptability allows it to serve as the foundation for everything from undergarments and sportswear to high-fashion outfits.

Here are the key advantages explained in detail:

Superior Comfort for Daily Wear

Comfort is the primary reason hosiery fabric is a favorite for garments worn close to the skin. Its soft texture, lightweight nature, and smooth surface make it gentle and non-irritating, even during extended wear.

This is why hosiery fabric is extensively used for undergarments, babywear, and loungewear where comfort cannot be compromised.

Excellent Stretch and Recovery

Hosiery fabric is knitted rather than woven, which gives it natural elasticity. When blended with fibers like elastane or Lycra, it provides even greater stretch and recovery.

This means the fabric molds to the body’s contours for a snug fit without losing its shape after multiple uses, ideal for leggings, activewear, and body-fit tops.

Breathability for Warm Weather

The knitted structure of hosiery fabric allows better airflow compared to tightly woven fabrics. This breathable quality keeps the wearer cool and comfortable in warmer climates, while also allowing moisture to evaporate quickly. Cotton hosiery fabrics, in particular, are excellent for tropical and humid regions.

Wide Variety in GSM, Patterns, and Textures

Hosiery fabric offers a remarkable variety, ranging from lightweight sheer fabrics (100-120 GSM) for lingerie to heavier structures (up to 350 GSM) for outerwear like pajamas or baby suits.

It also comes in multiple patterns such as plain, rib, interlock, and melange, giving manufacturers and designers endless options to create garments suited to different consumer needs.

Cost-Effectiveness Compared to Woven Fabrics

Because hosiery fabrics are produced efficiently using circular or flat knitting machines, they are often more cost-effective than woven fabrics.

They provide great performance and comfort without driving up garment costs, making them a go-to choice for mass-market apparel production.

Fashion Adaptability from Casual to High-End Garments

Hosiery fabric is not limited to basic everyday wear. Its adaptability allows it to be styled for various markets, from simple cotton T-shirts and pajamas to trendy athleisure wear and even luxury lingerie.

With options for printing, dyeing, and blending, hosiery fabric seamlessly bridges casual, functional, and fashion-forward segments.

Choosing the Right Hosiery Fabric

When selecting hosiery fabric, manufacturers and designers must consider several factors:

End-Use

Define whether the fabric is for lingerie, sportswear, children’s wear, or casual wear.

GSM (Fabric Weight)

Lightweight hosiery (100-140 GSM) is used for lingerie, while heavier fabric (200–350 GSM) suits outerwear.

Fabric Width

Available in various widths, choosing the right one helps optimize cutting and minimize fabric waste.

Blend and Composition

Natural fibers offer comfort, synthetics provide durability, and elastane adds stretch, blends balance these properties.

Wash Care

Ensure fabrics match the care requirements of the target garment market.

Caring for Hosiery Fabric

Hosiery fabrics are prized for their softness, stretchability, and delicate structure, but this also makes them more vulnerable to damage if not cared for properly.

Whether it’s lightweight lingerie, durable sportswear, or cozy loungewear, following the right care practices ensures that hosiery garments maintain their shape, elasticity, and overall quality for longer.

Here’s a detailed guide:

Wash in Cold or Lukewarm Water

Hosiery fabrics are often blended with elastane or spandex, which can lose elasticity when exposed to hot water. Cold or lukewarm water helps preserve the stretch and prevents premature sagging or shrinkage. It also reduces the risk of color fading, especially in darker garments.

Use Mild Detergents

Strong detergents and bleach can break down delicate fibers, reducing the softness and durability of hosiery fabric. Instead, choose a gentle liquid detergent designed for delicate or knitwear fabrics. This ensures effective cleaning without harsh chemical damage.

Hand Washing for Delicate Items

While many hosiery fabrics can withstand machine washing, delicate garments like stockings, tights, lingerie, and babywear benefit from hand washing. By soaking the fabric for a few minutes and gently rubbing with your hands, you minimize friction that can lead to pilling, snags, or holes.

Avoid Wringing or Twisting

Stretching or twisting hosiery fabric while removing excess water can permanently distort its shape. Instead, press the fabric gently between your palms or wrap it in a clean towel to absorb moisture. This method preserves the garment’s structure and prevents overstretching.

Dry Flat in the Shade

Direct sunlight and high heat can weaken fibers and cause fading. Dry hosiery garments flat on a clean, dry surface to maintain their shape and avoid stretching.

Hanging delicate hosiery, like stockings or lightweight tops, can cause them to elongate under their own weight.

Store Properly

Instead of hanging, which can stretch out lightweight knits, fold hosiery garments neatly and store them in drawers or fabric organizers.

For delicate pieces like stockings and tights, consider rolling them gently to avoid snags and tangles. Using fabric bags or pouches can also protect them from friction with other garments.

Conclusion

Hosiery fabric has transformed the textile and apparel landscape, offering a unique combination of comfort, elasticity, durability, and versatility. From undergarments and socks to sportswear and casual outfits, its applications are virtually endless.

As consumer demand shifts toward comfort-driven fashion and sustainable solutions, hosiery fabrics continue to adapt with new blends, finishes, and eco-friendly innovations.

For manufacturers, designers, and consumers alike, understanding the qualities and applications of hosiery fabrics is key to making informed choices that bring both functionality and style to everyday wear.