Imagine a fabric that combines incredible strength with surprising comfort, offering unparalleled versatility for countless applications.

Drill fabric is a durable cotton or linen textile, known for its tight twill weave that creates a distinctive diagonal pattern. This weave ensures exceptional strength and resilience, making drill ideal for heavy-duty applications.

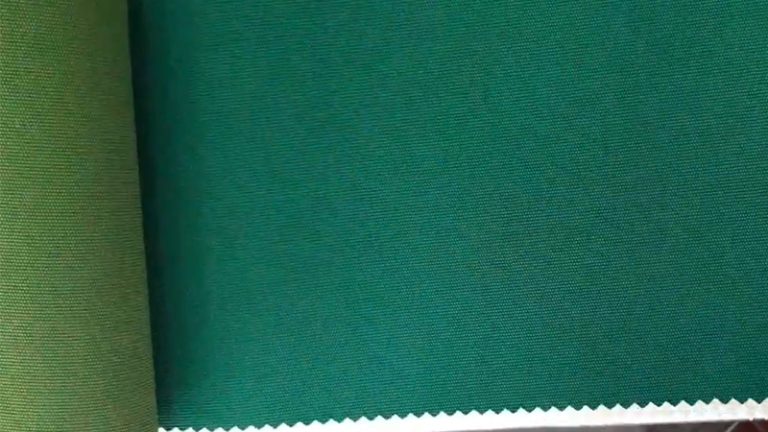

Unlike denim, its warp and weft threads are usually the same color, giving it a uniform appearance.

Typically medium to heavyweight, drill can also be made from 100% combed, pre-shrunk cotton to prevent shrinkage, or blended with synthetic fibers for added performance.

Its robust structure and natural fiber composition offer durability, breathability, and versatility, making it a preferred choice for workwear, uniforms, upholstery, and outdoor gear.

A Rich History: From Battlefields to Everyday Wear – The Enduring Legacy of Drill Fabric

Drill fabric’s history is deeply tied to moments of industrial, military, and cultural change. Emerging during the Industrial Revolution, its strength made it essential for laborers’ workwear.

In the 1840s, British troops in India wore white cotton drill uniforms dyed tan for camouflage, giving rise to khakis. Its military use peaked in World War II, cementing its reputation for resilience.

Post-war, veterans embraced drill’s comfort in civilian life, making it a staple of casual fashion. Today, it remains vital for uniforms, especially in hospitality, valued for its heat protection, durability, and comfort—a fabric that has truly shaped work, war, and style.

What Makes Drill Fabric Stand Out? Unpacking its Unique Qualities and Advantages

Drill fabric boasts an impressive array of characteristics that set it apart, making it a preferred choice for applications demanding both resilience and comfort.

Durability & Strength:

The defining characteristic of drill fabric is its exceptional durability and strength, allowing it to withstand significant wear and tear over time. T

his robustness is primarily due to its intricate construction: it is a versatile, sturdy cotton fabric created with coarse carded yarns woven into a dense pattern.

The very existence of its distinctive diagonal weaving contributes to its robust and lasting character, enabling it to endure extreme stress while maintaining its structural integrity.

It is recognized as a finely woven cloth. Its inherent strength makes it ideal for heavy-duty applications, ensuring that products made from drill fabric have an extended lifespan.

Comfort & Breathability

Despite its heavy-duty nature, drill fabric is remarkably noted for its optimum comfort and breathability. This essential quality is largely attributed to its primary component, cotton.

The fabric is also moisture-wicking, effectively drawing moisture away from the body, which significantly enhances comfort across a range of environments. It is naturally breathable and non-static due to its inherent moisture content.

A notable characteristic is its ability to absorb up to 65% of its weight when wet, dripping less than many other materials, which contributes to its practicality in various situations.

Depending on the specific application, drill fabric is available in both light and heavy weights, offering flexibility without compromising on comfort.

Ease of Care

For all its strength, cotton drill fabric is surprisingly easy to work with and generally straightforward to care for. For new fabric, simply washing and tumble-drying can help soften it.

It is advisable to wash the cloth before sewing to pre-shrink it and to eliminate any extra discoloration that might occur.

While it doesn’t often require ironing, if needed, a regular iron setting is suitable. This low-maintenance aspect adds to its appeal for both manufacturers and end-users.

Other Notable Features

Beyond its core attributes, drill fabric possesses several other beneficial characteristics:

- Shine: It exhibits a light sheen, adding a subtle aesthetic quality.

- Opacity: Drill fabric is inherently opaque, providing good coverage for clothing and upholstery.

- Eco-Friendly: For those mindful of environmental impact, drill fabric is a positive choice as it is biodegradable and recyclable.

- Versatility: It is truly a great utility fabric, available in various types and colors, making it adaptable to a wide array of designs and purposes.

- Drapability & Feel: It generally feels soft, dries slowly, and is easy to drape, particularly cotton drill variations.

- Resilience to Harsh Treatments: Cotton drill can even be boiled and bleached, further demonstrating its robust nature.

These combined qualities underscore why drill fabric continues to be a top choice for projects demanding reliability, comfort, and ease of management.

Exploring the Different Types of Drill Fabrics: Varieties for Every Need

The versatility of drill fabric is further enhanced by its existence in several distinct types, each formulated with specific applications in mind.

Cotton Drill Fabrics

This is by far the most common and widely recognized type of drill fabric. As its name suggests, it is typically made from 100% cotton.

Cotton drill textile is the go-to choice for classic applications such as workwear, uniforms, and outdoor gear, where its natural strength, breathability, and durability are paramount.

Polyester Drill Fabrics

For applications demanding even greater resilience, polyester drill fabric offers a compelling alternative. This type is manufactured from a blend of polyester and cotton.

The inclusion of polyester significantly enhances its performance, making it typically more durable and resistant to wear and tear compared to pure cotton drill textile.

Due to its superior strength and longevity, polyester drill fabric is often utilized in upholstery and other applications where extreme strength is a primary consideration.

Stretch Drill Fabrics

Addressing the modern demand for comfort and flexibility, stretch drill fabric is engineered from a blend of cotton and lycra (or other stretch fibers like spandex).

This composition endows the fabric with high durability alongside a crucial element of stretch, making it perfectly suited for applications that require both flexibility and comfort.

It has become a popular choice for trousers, womenswear, and menswear, where ease of movement is as important as durability.

Nylon Drill Fabrics

Primarily composed of nylon, this variant of drill fabric stands out for its exceptionally high durability and resistance to wear and tear.

Nylon’s inherent strength makes this drill fabric particularly robust. Consequently, it is commonly employed in the manufacturing of resilient items such as bags and upholstery, where the material must withstand rigorous daily use.

Diverse Applications: Where You’ll Find Durable Drill Fabric

The robust and adaptable nature of drill fabric lends itself to an incredibly diverse range of applications, establishing it as a staple across various industries and in everyday life.

Clothing & Apparel:

Drill cloth’s strength and durability make it a perennial favorite for workwear. It is extensively used for professional attire, including uniforms, coveralls, shirts, safari jackets, military uniforms, and chef coats.

Its ability to withstand rigorous use and provide a degree of protection, such as shielding from heat for chefs, makes it ideal for these demanding environments. Beyond functionality, drill fabric is also an essential material in fashion items.

Its unique texture and inherent strength are leveraged in creating stylish yet durable pieces like jackets, pants, and heavier-weight dresses.

The capacity for it to be printed in various patterns and colors further expands its appeal in the fashion sector, allowing designers to combine robust quality with aesthetic versatility.

Home Furnishing & Upholstery

In interior design and home furnishings, drill fabric is highly valued for its hard-wearing properties. It is commonly utilized for furniture covers, cushion covers, and curtains, providing both durability and a clean, structured appearance. Its ability to withstand consistent use makes it perfect for high-traffic areas in a home or commercial setting.

Accessories & More

The utility of drill fabric extends well beyond apparel and home goods. Its robust nature makes it suitable for various accessories and specialized items:

- Outdoor Gear: It is frequently used for items like tents, canopies, and canvas due to its resistance to elements and durability.

- Bags and Footwear: Its resilience makes it an excellent choice for crafting durable bags and fabric-covered shoes.

- Scarves: Some types can even be fashioned into scarves, showcasing its softer side depending on the specific weave and finish.

From rugged work environments to chic fashion statements and durable household items, drill fabric consistently proves its value through its multifaceted applications.

Drill Fabric vs. Twill Fabric: A Detailed Comparison

Understanding the distinction between drill fabric and general twill fabric is crucial, as both are renowned for their strength but serve slightly different purposes.

Fundamentally, both drill and twill fabrics are known for their durability and strength, sharing the characteristic diagonal weave that defines the twill family.

Drill fabric is generally considered the more robust of the two. Its tightly packed yarns and heavier weight create a denser structure, offering exceptional resistance to abrasion and tearing.

This makes drill ideal for heavy-duty applications—military uniforms, industrial workwear, and hard-wearing upholstery—where maximum endurance is essential.

Twill fabric, while still strong, is often woven with a slightly looser construction and in lighter weights.

This results in a softer hand feel and more fluid drape, lending itself to everyday garments, fashion apparel, and home furnishings where comfort and flexibility are as important as strength.

Caring for Your Drill Fabric Items: Maintaining Longevity and Quality

To ensure that your garments and items made from drill material maintain their quality and last for a long time, proper care is essential.

Despite its reputation for strength and durability, drill fabric still benefits greatly from appropriate maintenance.

Washing Instructions:

- Always use cold water and a mild detergent when washing drill cloth.

- It is crucial to avoid using bleach or fabric softeners, as these chemicals can potentially damage the fabric fibers over time.

- For new fabric, it is recommended that the cloth be washed before sewing to pre-shrink it and to remove any potential extra discoloration that might bleed onto other fabrics. This step helps ensure the finished product maintains its size and color stability.

Drying Guidelines:

- The best method for drying your drill material garments is to hang-dry them. This allows the fabric to dry naturally without exposure to harsh heat.

- If tumble-drying is necessary, use a low-heat setting. High heat can cause the fabric to shrink significantly, impacting the fit and appearance of your items.

Ironing Tips:

- Drill fabric typically does not require frequent ironing. Its inherent stiffness and dense weave often result in a naturally smooth appearance.

- However, if ironing is needed, make sure to use a low-heat setting. Using high heat can lead to the fabric melting or becoming discolored.

General Advice:

Always make it a point to check the label on your drill clothing items for any specific care instructions. Different types of drill textiles, especially blends, may have unique requirements.

Following these instructions is vital to ensuring the best results and preserving the integrity of the fabric. By adhering to these simple care guidelines, you can significantly extend the lifespan and maintain the pristine condition of your drill fabric items.

Potential Considerations: Understanding Minor Drawbacks for a Balanced View

While drill fabric offers a plethora of advantages, a balanced understanding also requires acknowledging a few potential considerations that might influence its suitability for specific uses.

Stiffness

One common observation is that some types of drill textiles can be somewhat stiff and potentially uncomfortable to wear, especially when they are brand new or first purchased.

This initial rigidity is often a direct consequence of its dense, tight weave, which contributes to its renowned durability.

However, this stiffness often softens significantly after a few washes and wears, becoming more pliable and comfortable over time.

Maintenance Nuances

Although drill material is generally considered easy to care for, it’s worth noting that certain types of drill textiles or specific applications may require special treatment or cleaning methods.

This isn’t a universal rule, but rather a reminder that unique blends or finishes on drill fabric might necessitate a departure from standard care routines. Always referring to the product’s care label is the best practice to avoid any issues.

Conclusion: The Enduring Appeal and Future Significance of Drill Fabric

Drill fabric stands as a formidable heavy-duty cotton fabric, distinguished by its exceptional strength, durability, and resistance to wear and tear.

Its unique twill weave and robust construction make it an ideal choice for a diverse range of applications, particularly in workwear, uniforms, and outdoor gear.

Beyond its sheer resilience, drill fabric also offers practical benefits such as its ability to wick away moisture, contributing to its comfort in various settings.

From its historical role in outfitting armies and laborers to its contemporary presence in fashion and home furnishings, drill fabric has consistently proven its value.

Its distinctive qualities and remarkable adaptability guarantee its continued significance in the textile industry for many years to come.

Whether you are a designer seeking a reliable material for a new collection, a business needing durable uniforms, or an individual looking for long-lasting home goods, drill fabric offers a compelling blend of strength, comfort, and historical prestige.

Explore the possibilities and discover how this enduring textile can elevate your next project or purchase.